FEROVAN®

AMG Vanadium produces low-aluminum “Green Vanadium,” known as FEROVAN®, with a carbon footprint five times smaller than vanadium produced through traditional mining. FEROVAN® offers distinct advantages to steelmakers, including maximum recoveries and a range of other benefits.

AMG Vanadium is a trusted partner to North American steelmakers, supplying ferrovanadium for over 50 years. Steelmakers know the importance of achieving the highest and most consistent vanadium recovery for every dollar spent, and AMG’s V-CYCLE® process produces FEROVAN® that offers the solution. FEROVAN® offers distinct advantages – including maximum recoveries, unrivaled solubility, and many other essential benefits:

- FEROVAN® is produced under AMG V’s ISO 9001:2015 registered Quality Management System to meet the most exacting demands of today’s steelmaking producers and consumers.

- FEROVAN® is perfect for EAF steel as the vanadium readily combines with existing nitrogen without increasing nitrogen or carbon content.

- FEROVAN®’s high density, 6.4 g/cc (90% of liquid steel’s density) ensures good melt penetration which minimizes alloy flotation and front-to-back ladle analysis variations.

- FEROVAN® is the most effective vanadium additive for all carbon and alloy steels and alloyed cast irons. This application versatility makes it ideal for a broad range of applications: structural steel, HSLA steel, reinforcing bar, line pipe, and angle. It is also suitable for all primary melting processes including electric arc, induction and basic oxygen furnaces, and for use in secondary refining stations such as vacuum degassers and ladle furnaces. The resulting vanadium addition is well known for it’s ease of use in steel processing, including excellent castability, reduced roll forces compared to other microalloys, and effective precipitation strengthening with normal cooling cycles after rolling.

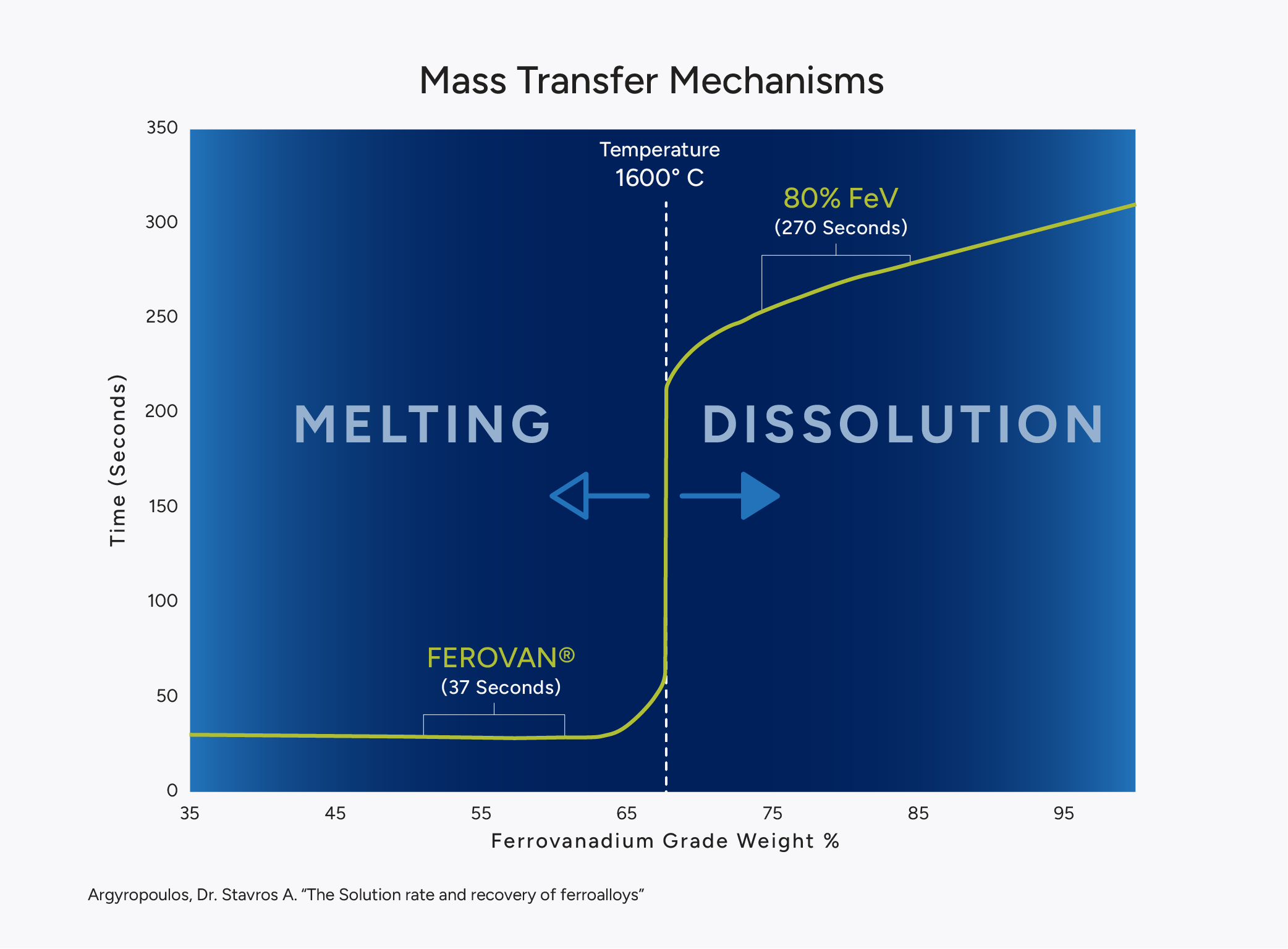

Mass Transfer Mechanisms, in the chart below shows melting/dissolution time required for 2.54 cm diameter cylinders of ferrovanadium to dissolve into a bath of steel at 1600°C (1873°K), showing FEROVAN®’s superior solubility properties.

In addition to the product quality benefits of FEROVAN®, AMG Vanadium’s V-CYCLE® process enables the production of “Green Vanadium,” supporting the sustainability efforts of our steel customers. More specifically, AMG’s V-CYCLE® process enables CO2 reduction benefits in the steel supply chain, and our FEROVAN® product allows a weight reduction of 20-40% compared to standard carbon steel used for the same function.