Our History

$300M Zanesville Plant becomes fully operational, doubling AMG Vanadium’s spent catalyst processing and metal reclamation production capabilities

Name change from AMG Vanadium Inc. to AMG Vanadium LLC

Name change from Metallurg Vanadium to AMG Vanadium Inc.

Metallurg Vanadium becomes part of AMG’s Advanced Materials Unit

Cambridge plant is incorporated as Metallurg Vanadium Corporation

Strategic business model shift to become spent catalyst centric

Metallurg, Inc. Is acquired by Safeguard International Fund

Metallurg, Inc. Acquires Cambridge Plant

VCA is merged into Foote Mineral Company

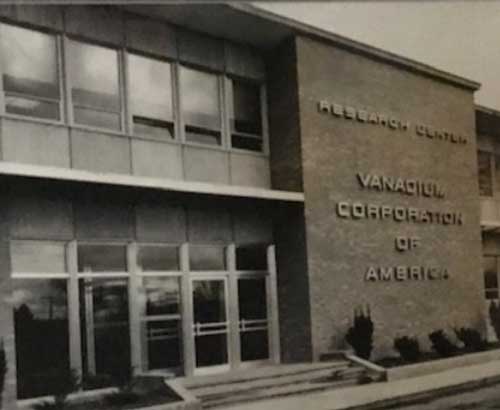

The Cambridge Site is founded by Vanadium Corporation of America (VCA)

The Vanadium Corporation of America (VCA) was organized in September 1919 to carry on the operations at Mira Ragra. With the rapid growth of the American metals market, VCA began expanding with various acquisition across the US and in 1952 founded the ferro alloy plant in Cambridge, Ohio (current site of AMG Vanadium) with construction completed in 1953. The Cambridge facility allowed VCA to relocate its vanadium production facility from Pittsburgh to the geographic heart of its main customer, the U.S. Steel industry. In 1967, VCA merged with the Foote Mineral Corporation (Foote Mineral), a subsidiary of Newmont Mining Company.

Foote Mineral completed updates to the facility in 1970 which allowed the company to produce a niche market ferrovanadium product with several recognizable metallurgical advantages in steelmaking called Ferovan®. These updates also allowed the company to utilize, at the time, an economical vanadium bearing slag for a raw material source. FMC operated the facility until 1987, when Shieldalloy Metallurgical Corporation (SMC), a subsidiary of Metallurg, Inc. and predecessor company of AMG Vanadium LLC (AMG V) acquired the business.

Upon acquiring the facility, products manufactured included different grades of ferrovanadium, complex boron alloys, vanadium chemicals, vanadium containing iron ingots, and slag co-products. However, SMC recognized disadvantages with the facility’s raw material supply and began making changes in this area and the product mix in addition to completing expansion updates such as commissioning a new roaster in 1991.

In 2006, the Cambridge facility was incorporated as Metallurg Vanadium Corporation and then merged into the Advanced Metallurgical Group NV (AMG) in 2007. Additionally, under new leadership in the early 2000’s, a major strategic decision in the business model was made which changed the way the company operated and sourced raw materials. This change ultimately became the new mission wherein AMG V evolved from an alloy producer to a spent catalyst full metal reclamation processor, as North American petroleum refiners desire the spent catalysts to be processed in an environmentally secure manner which AMG V reliably provides. This change in raw materials also allowed AMG V to significantly upgrade the metallic co-product, FeNiMoly®. Additionally, AMG’s key emphasis on environmental stewardship led to multiple investments in the facility including: state-of-the-art raw material storage buildings, an additional roaster in 2016, and ISO Certificates which recognize the Safety, Environmental, and Quality management systems of the Cambridge business. All of this has led AMG V to where it is today – the leading processor of spent catalyst and producer of ferrovanadium.