Our Sustainable Approach

AMG V

Commitments

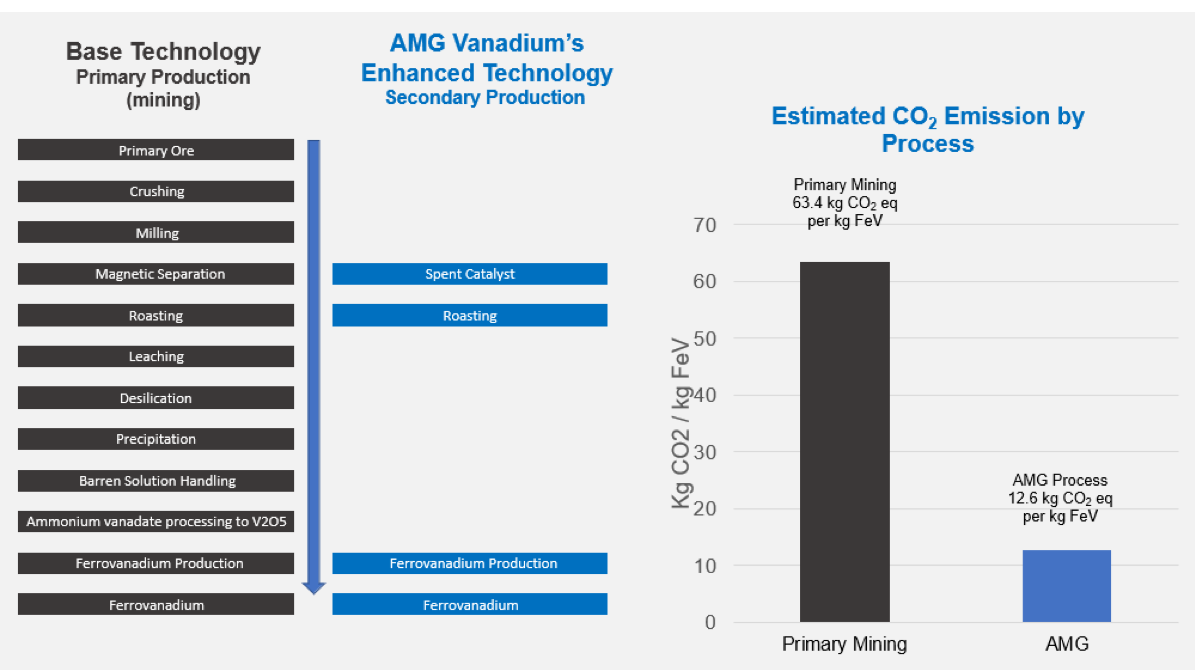

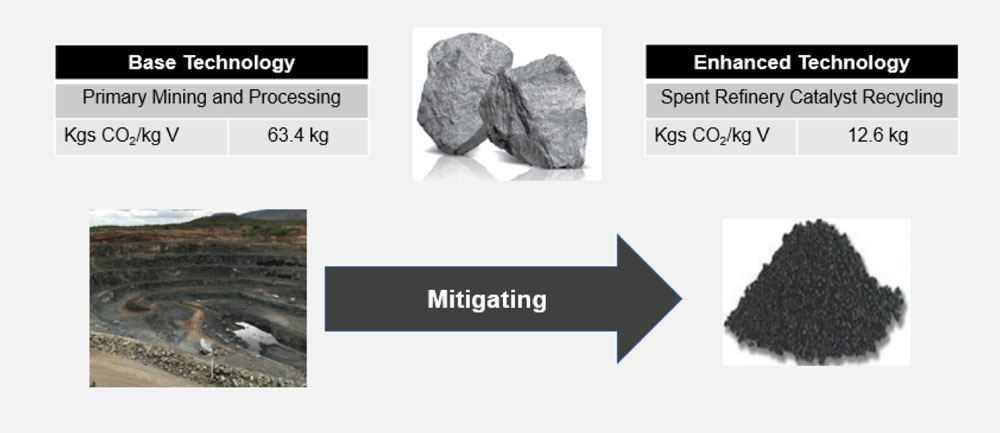

To quantify this, we engaged a third-party organization to conduct a Carbon Footprint analysis comparing AMG V’s proprietary V-CYCLE® recycling process to produce ferrovanadium (Ferovan®) with ferrovanadium produced from the traditional primary mining route. The Carbon Footprint assessment considers AMG Vanadium’s manufacture of ferrovanadium, where it acquires vanadium from a secondary source, and compares this with the manufacture of a generic ferrovanadium product, where the vanadium is supplied from a primary source. The assessment also considers the greenhouse gas (GHG) emissions mitigation benefits achieved from the use of vanadium in steel alloys, compared with standard steel alloys.

Carbon Footprint – Primary vs Secondary

Mitigating

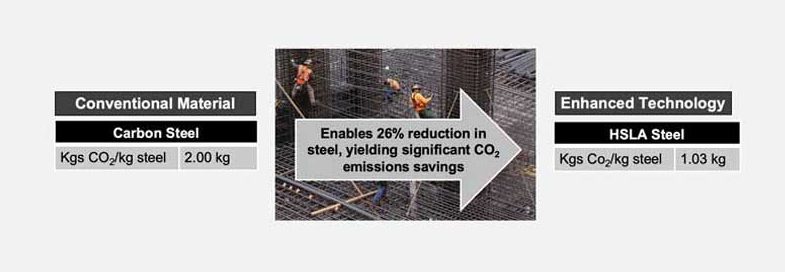

In addition to the CO2 mitigating benefits of AMG Vanadium’s environmentally superior technology, the use of vanadium in steel alloys improves the tensile strength of the steel, which results in between 20 and 40% less (by mass) of vanadium steel used compared with standard carbon steel for the equivalent function. The assessment assumed the typical weight of 26% resulting in the equivalent functionality of 1 kg of standard carbon steel, only 0.741 kg of vanadium steel required. This significant weight reduction enables a significant reduction in the carbon footprint of structures not only as a result of lower steel requirements but also resulting from reductions from fabrication and transportation.

Enabling

Sustainability Reporting

Global Reporting Initiative

We are a registered Organizational Stakeholder of the Global Reporting Initiative (GRI) and support the mission of the GRI to develop globally accepted sustainability reporting guidelines through a global, multi-stakeholder process.

United Nations Global Compact

We commit our support to the principles of the United Nations Global Compact, a strategic policy initiative for businesses that are committed to aligning their operations and strategies with ten universally accepted principles in areas of human rights, labor, the environment and anti-corruption.