Spent Catalyst Services

AMG Vanadium’s spent catalyst recycling services and V-CYCLE® process provide risk elimination for global refiners.

V-CYCLE®

AMG’s proprietary V-CYCLE® roasting and pyrometallurgical metal recovery process delivers substantial commercial value and environmental risk elimination for refinery partners. By responsibly recycling spent catalysts, we reclaim valuable metals, transforming them into ferrovanadium and other alloys for the steel industry.

Full Calcine/Roast

AMG V’s roasting process eliminates the hazardous self-heating characteristic of spent catalyst by converting the metal sulfides into metal oxides. Free oil and poly-aromatic hydrocarbons are also fully eliminated. Roasted catalyst is ready for metals recovery.

Metal Recovery

Through its proprietary V-CYCLE® process, AMG V extracts and reclaims the metal from alumina-based catalyst in our two-step pyrometallurgical operation. Roasted catalyst is melted into ferrovanadium and other alloys in our Electric Arc Furnaces, yielding no process wastewater, the industry’s lowest overall emissions (solid waste, air, and water), and the highest conversion to saleable products ratio in the industry.

Responsible Materials Management

AMG V’s strict controls and procedures ensure that your catalyst in our care is fully converted, not sent to landfill. Our bulk storage buildings are purpose-built to manage oil-laden catalyst in a controlled storage environment. We use segregated inventory storage bins, and our multi-layer sub-floor liner system captures and contains any free-flowing liquids.

Materials are fully protected from the environment throughout the entire process. Conveyors are fully enclosed, as are trucks used to transport material on our property. Our bulk rail unloading system contains the catalyst and oil until it reaches the catalyst storage building. Roll-offs, bins and other containers are unloaded inside the same building for bulk storage.

In addition to responsible material management, this allows a clean and safe working environment for employees and visitors.

Sustainability and Reporting

Green Vanadium – AMG’s proprietary V-CYCLE® waste processing and metal reclamation services and its Cambridge FEROVAN® production process create industry-leading CO2 reduction. We produce ferrovanadium while generating 80% less CO2 than mined vanadium ore. This is important to the steel mills who purchase our product and use that vanadium to eliminate millions of tons of CO2 per year. AMG V has a third-party methodology for calculating the CO2 reduction resulting from the recovery of vanadium from your spent catalyst and will be glad to provide you with customized information after processing. Furthermore, AMG Vanadium’s recycling and reporting support the ESG improvement efforts of today’s refineries.

Our Sustainable Approach

AMG V will provide documentation required to support your regulatory requirements, including manifests, Movement Documents and Certificates of Recycling. Other reports needed to support refinery efforts to improve reportable sustainability performance and ESG scores can also be provided. We will work with you to support your specific needs.

Metal Estimations

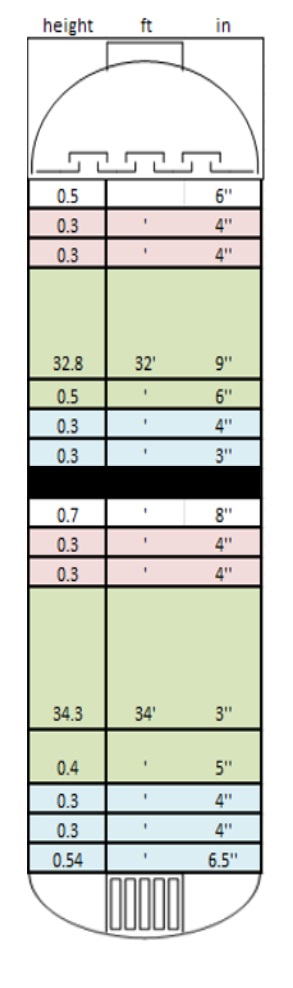

For our fixed bed refinery partners, our experience in the industry allows AMG V to aid in predicting metal percentages and commercial transaction results. These estimations can help with budgeting preparation and decision making. We do this using fixed bed reactor loading diagrams and metal laydown estimations from your process engineers.

Laboratory Capabilities and Waste Profile

AMG’s onsite lab is capable of and experienced in assaying your catalyst. We sample and analyze every shipment of catalyst to support commercial transactions and streamline invoicing. No need to engage a third party.

AMG V’s full-service support during the sample and profile process can make setting up the transaction as easy as possible for the refinery. We do this often, and we understand each refinery may have limited changeouts per year.

Logistics

Our experience moving catalysts in all potential packaging via all modes of transport can help identify the most efficient and cost-effective freight options. We have significant experience moving catalyst by rail in North America and containerized via ocean. We can manage this effort for our refinery partners, including significant assistance in developing Basel-compliant transport documentation.

Catalyst Disposition Consulting

A relationship with AMG V gives you access to our refinery waste reclamation experience. Let’s discuss your wastes and determine which are a good fit for our process. For the rest, we will support your efforts to fully recycle your waste streams.

Click here to learn more about AMG’s Industry Benchmark solution and risk mitigation/elimination for refinery partners.